*All client names and logos have been changed or removed for client confidentiality

Objective

Being the team at the heart of one of the largest automotive manufacturers in the world, the Demand and Supply Management Team’s main responsibility is to ensure that all vehicles headed to all U.S dealers make it to their destination within a very specific timing window. However, with an outdated supply chain monitoring system, it was becoming nearly impossible during and post pandemic to monitor and accurately forecast the arrival of vehicles and shipments to their destinations. The vast responsibility of monitoring vehicles through the supply chain pipeline, extends to intervening when a vehicle or entire vehicle shipment is delayed due to external factors like weather or vehicle damage during transit. All these factors, coupled with an outdated system, ways of working, and no clear definition of the DSM team’s main responsibility, it became nearly impossible for the team to accurately forecast a vehicle’s arrival, this inaccuracy caused major upset amongst internal teams, as well as dealers and consumers.

Role

This extensive project with our client spanned over a year, allowing me to wear many hats, including UX/UI designer, product designer and branding lead.

Part 1: Visioning Phase

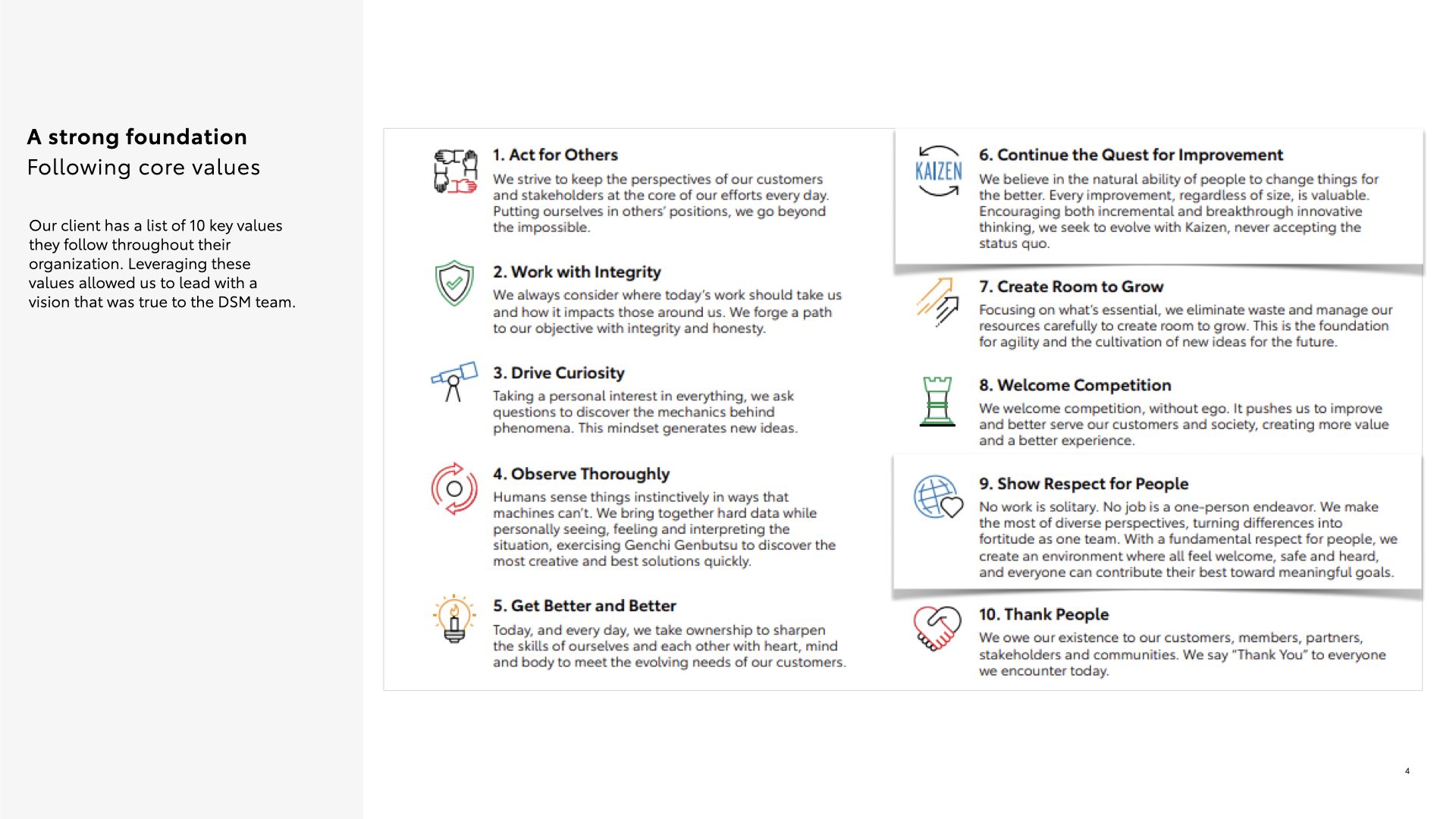

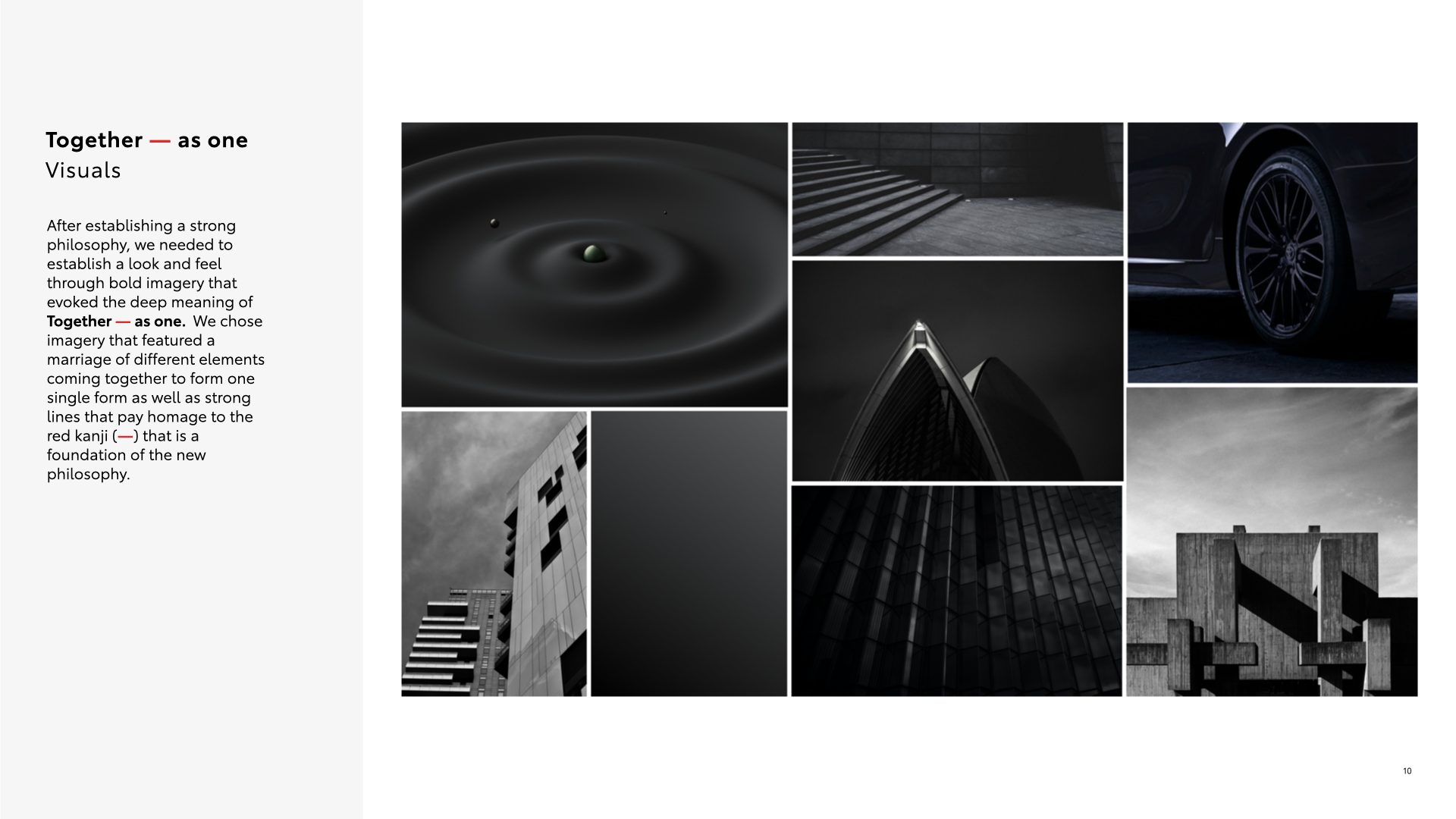

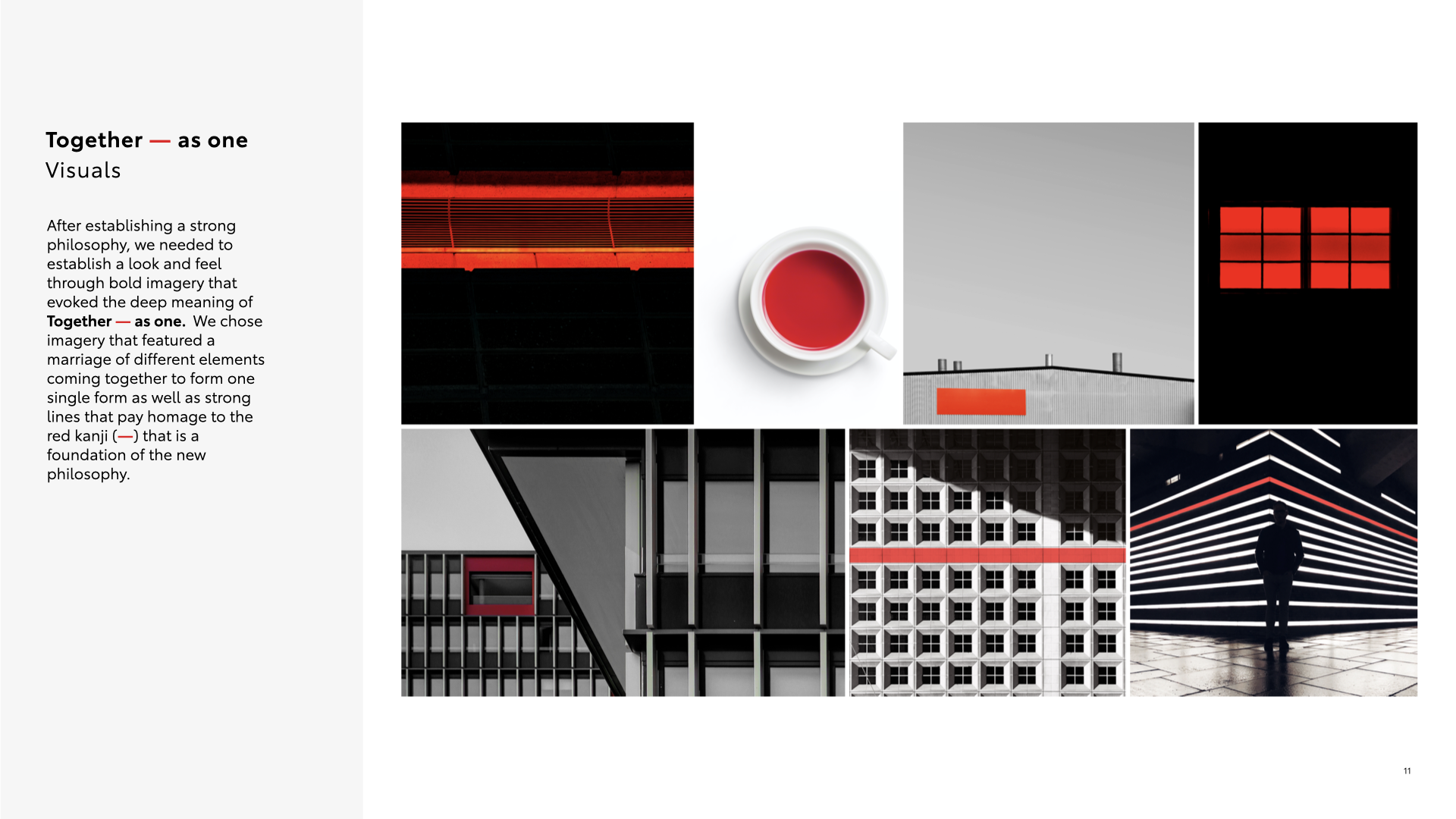

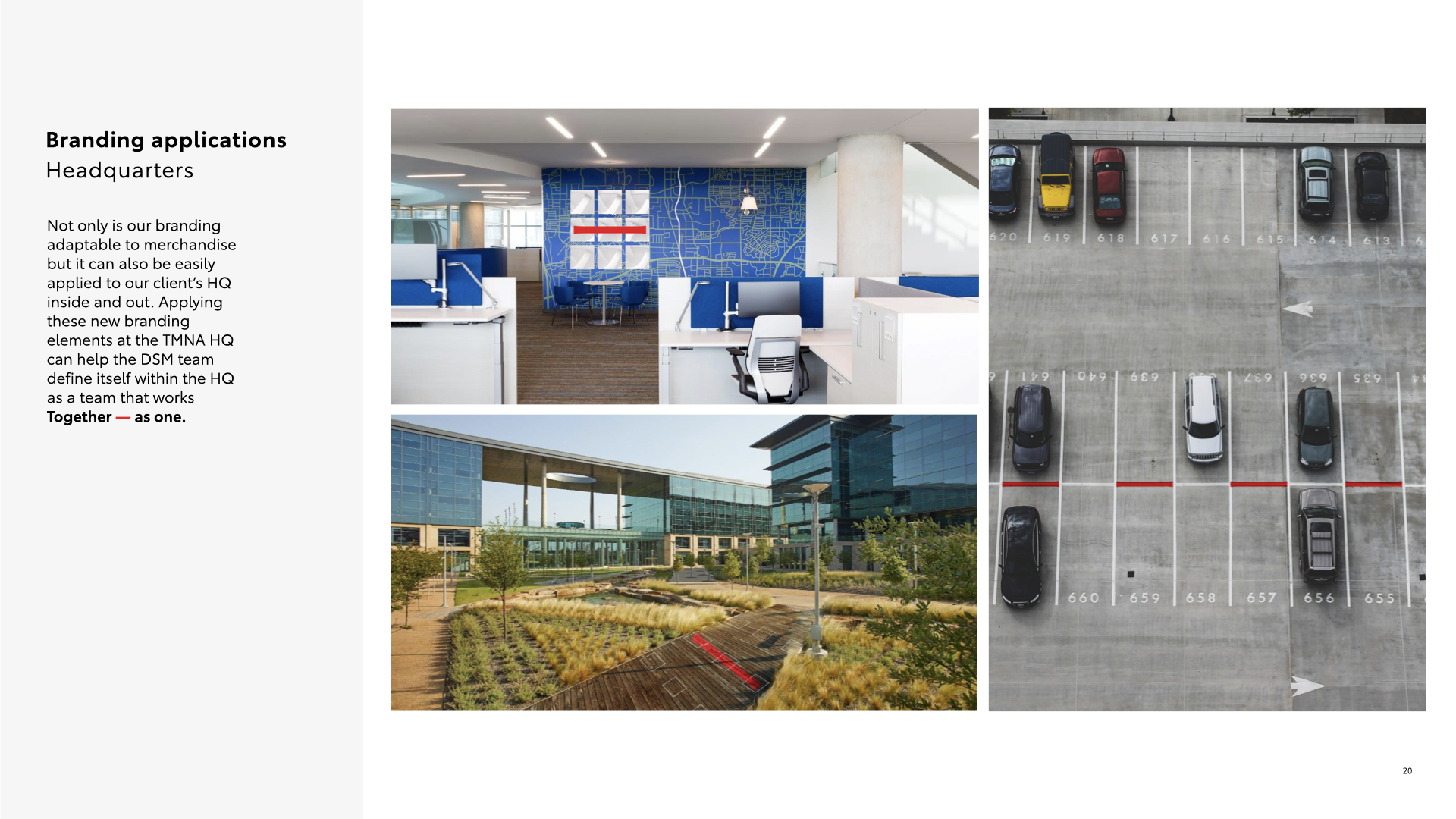

During our early stages of working with our client, we needed to not only create extensive buy in by showing them where we could take their company but we needed to develop a defined brand (from the ground up) that uplifted the DSM team as the supply chain leader (and main artery) of the organization. This team was plagued not only by outdated ways of working and legacy systems that left them unable to keep up with vehicle supply and demand but also by outdated branding and identities. Our strategy and main focus during the visioning phase became working closely with the key stakeholders and client executives on ideating and envisioning this future by starting with building and re-engineering a new brand identity for their demand and supply management (DSM) team.

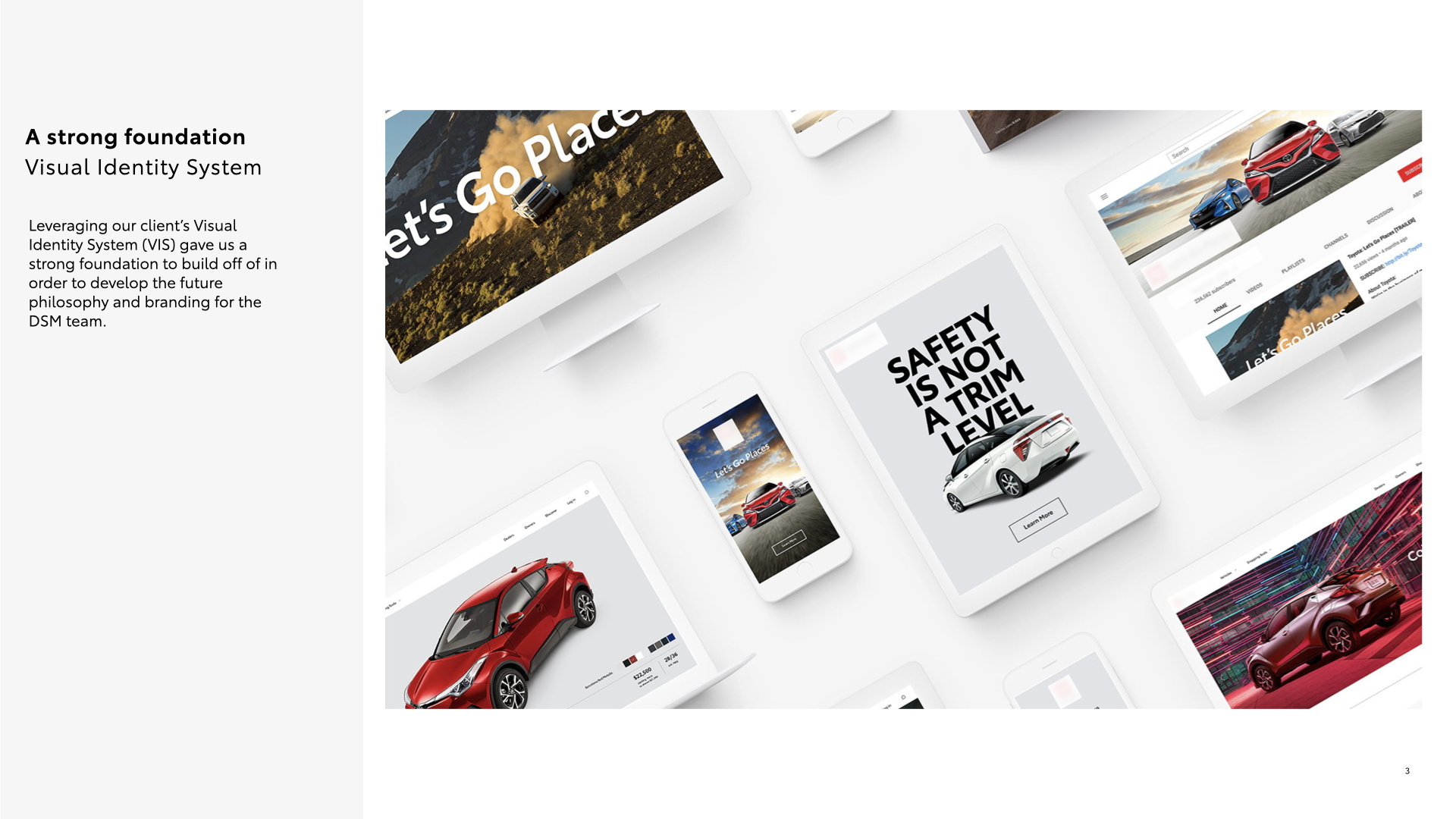

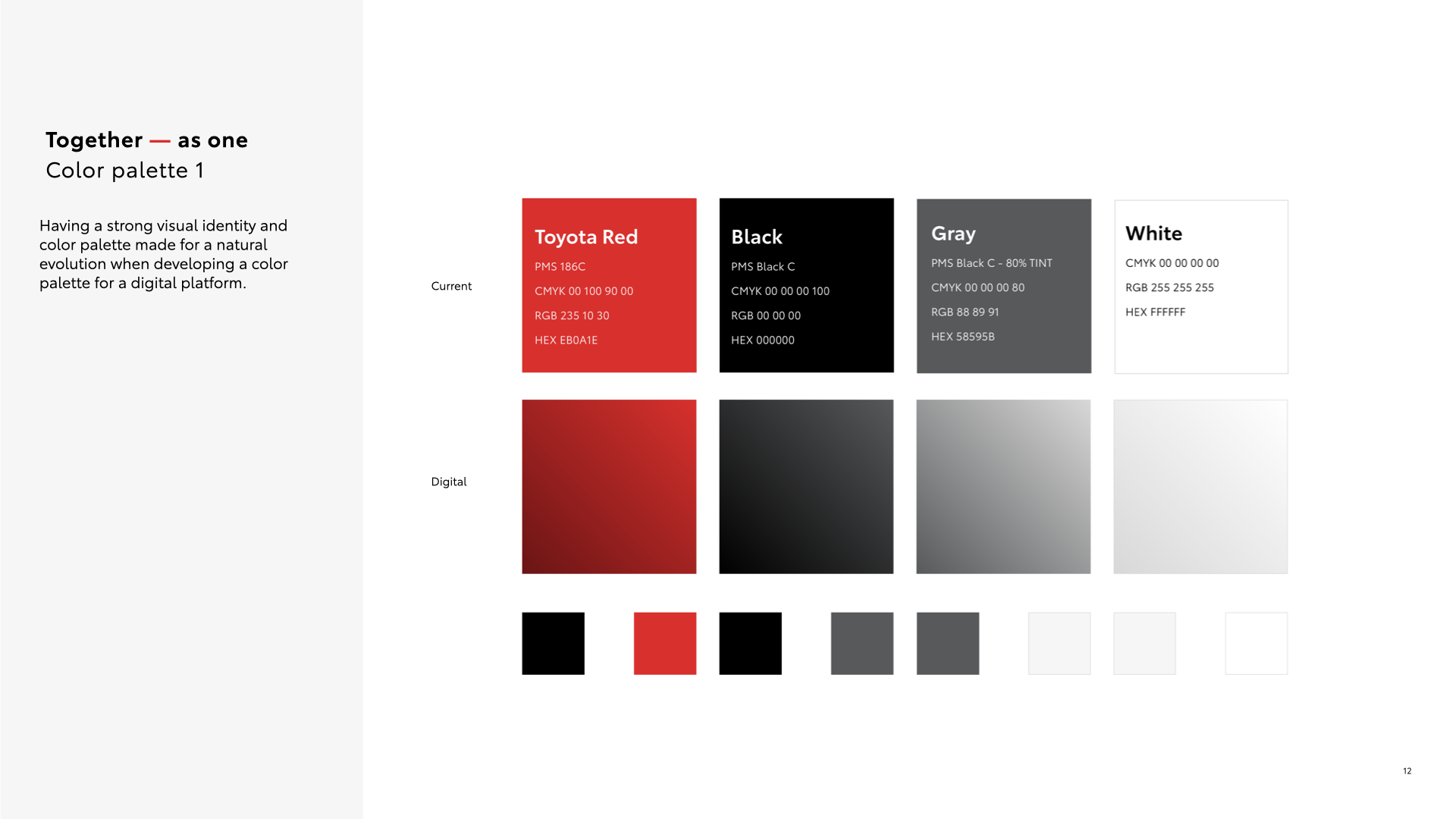

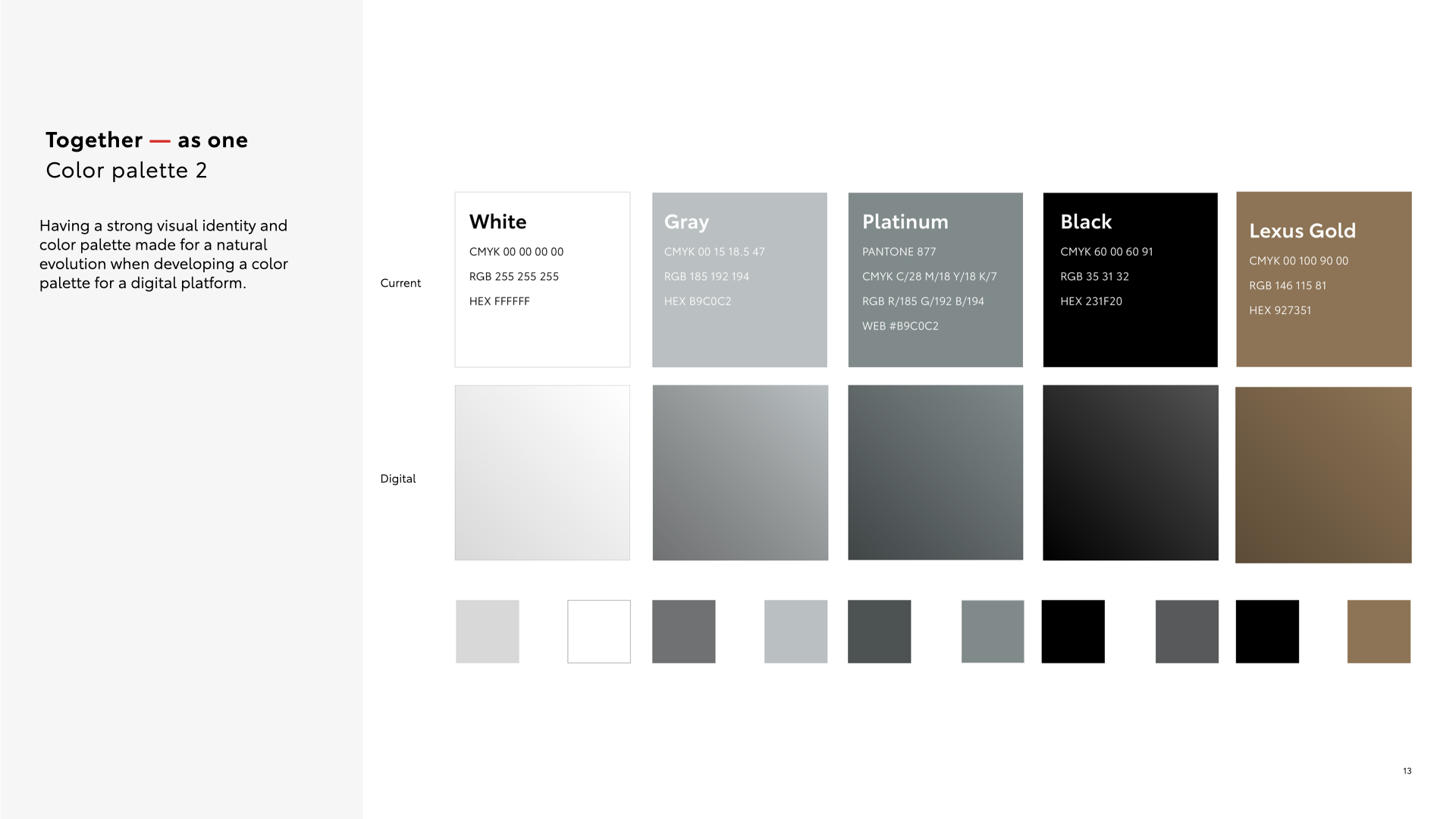

Starting with a strong foundation

Leveraging our client’s current Visual Identity System (VIS) gave us a strong foundation to build off of in order to develop the future philosophy and brand identity for our client’s DSM team.

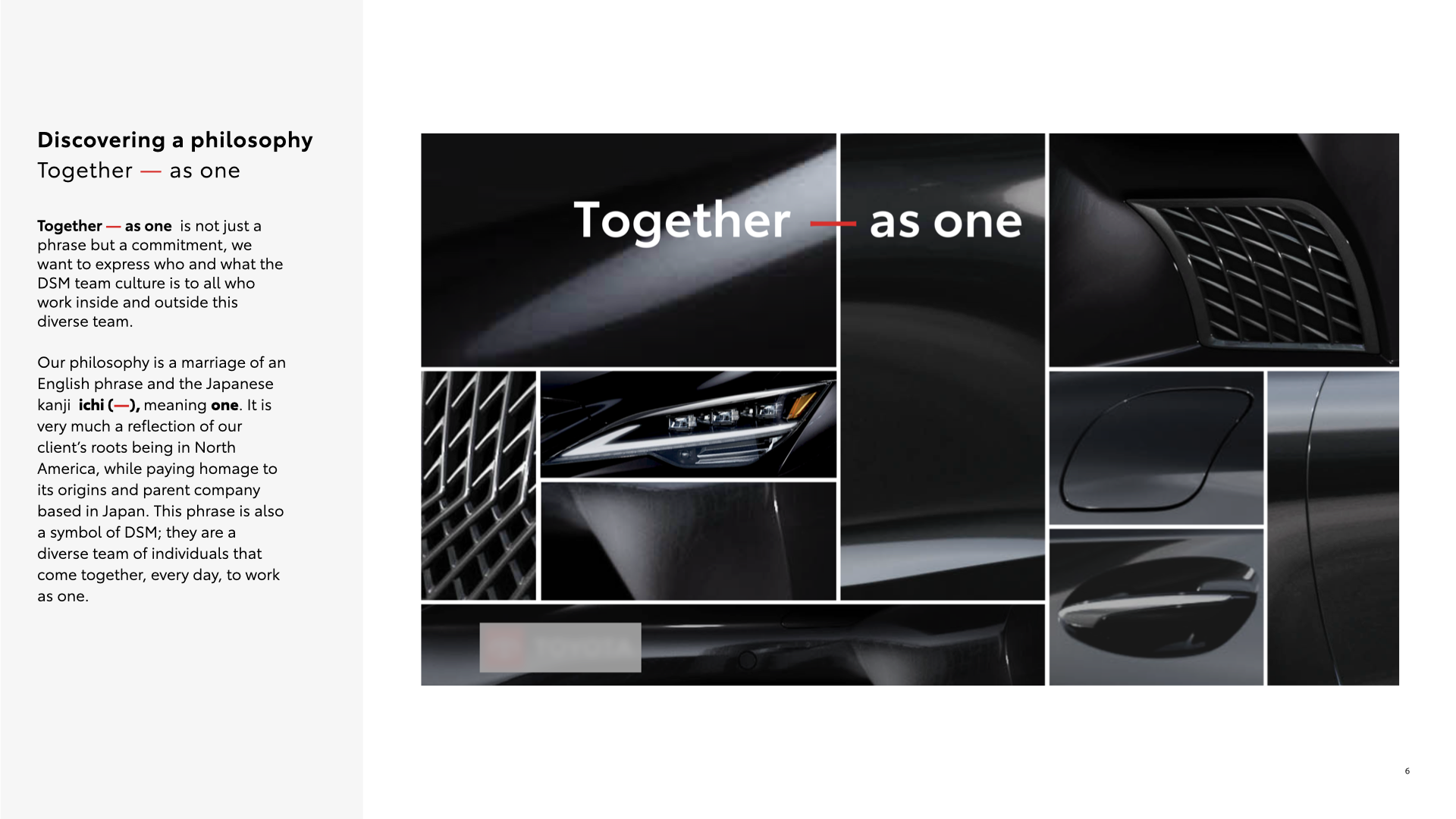

Discovering a Philosophy

Our client may be based in Plano Texas but its roots are in Japan where its parent company resides. When we were first tasked with the reinvention of the DSM branding a single word continuously stuck in our minds. One or in Japanese, ichi (—). This word is the perfect representation of unity and togetherness that are the core values of the DSM team.

Developing a Mantra

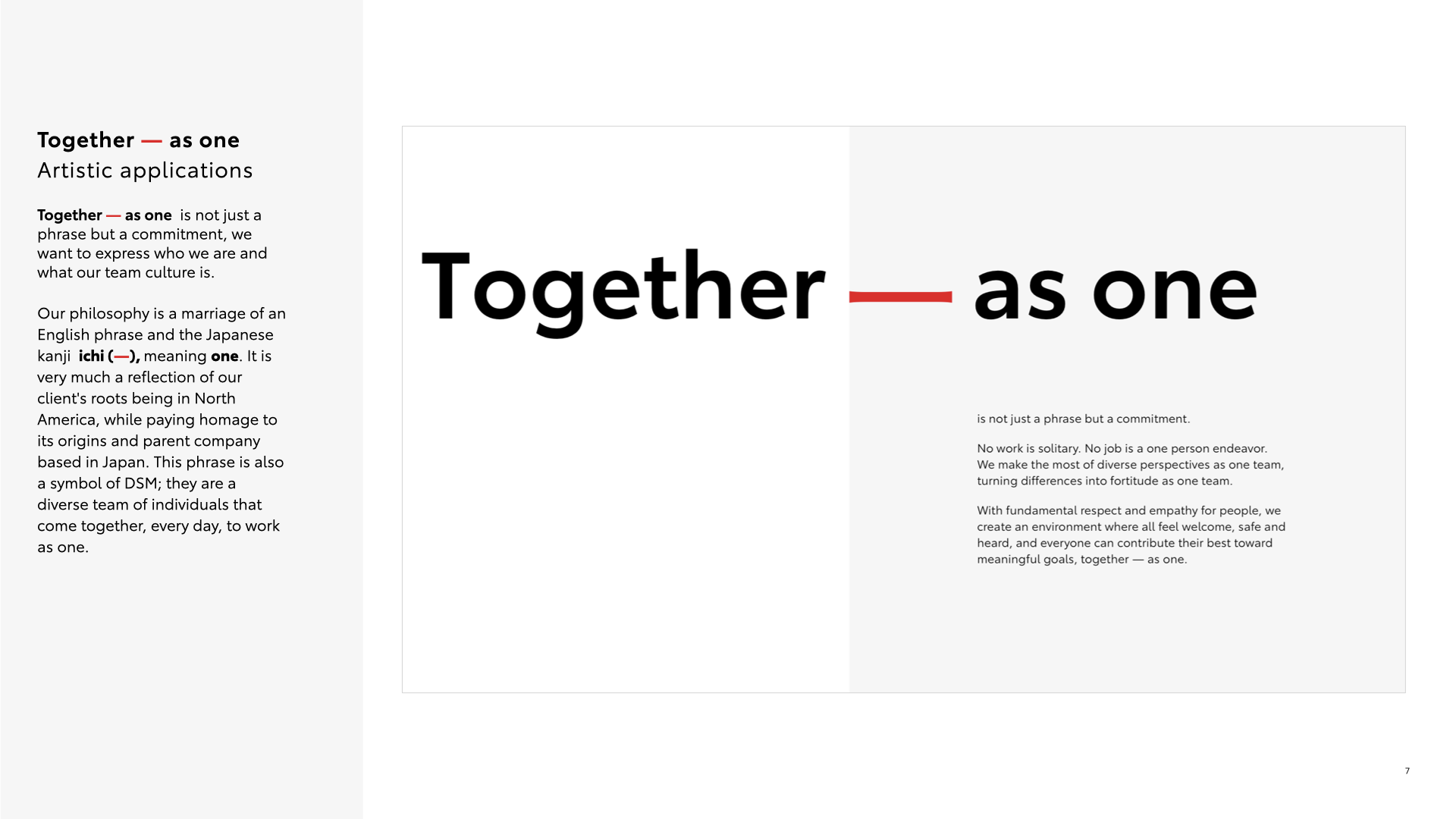

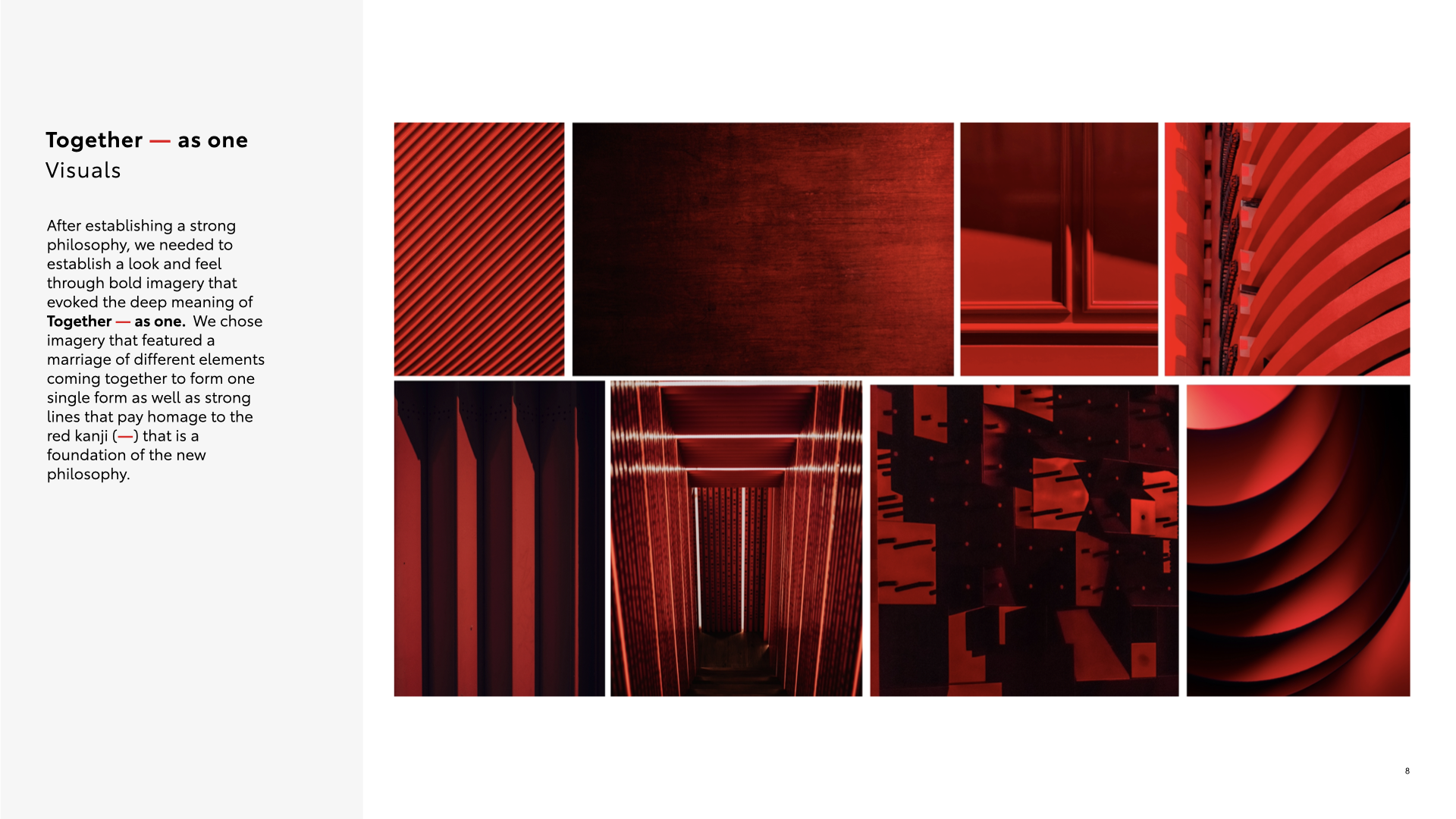

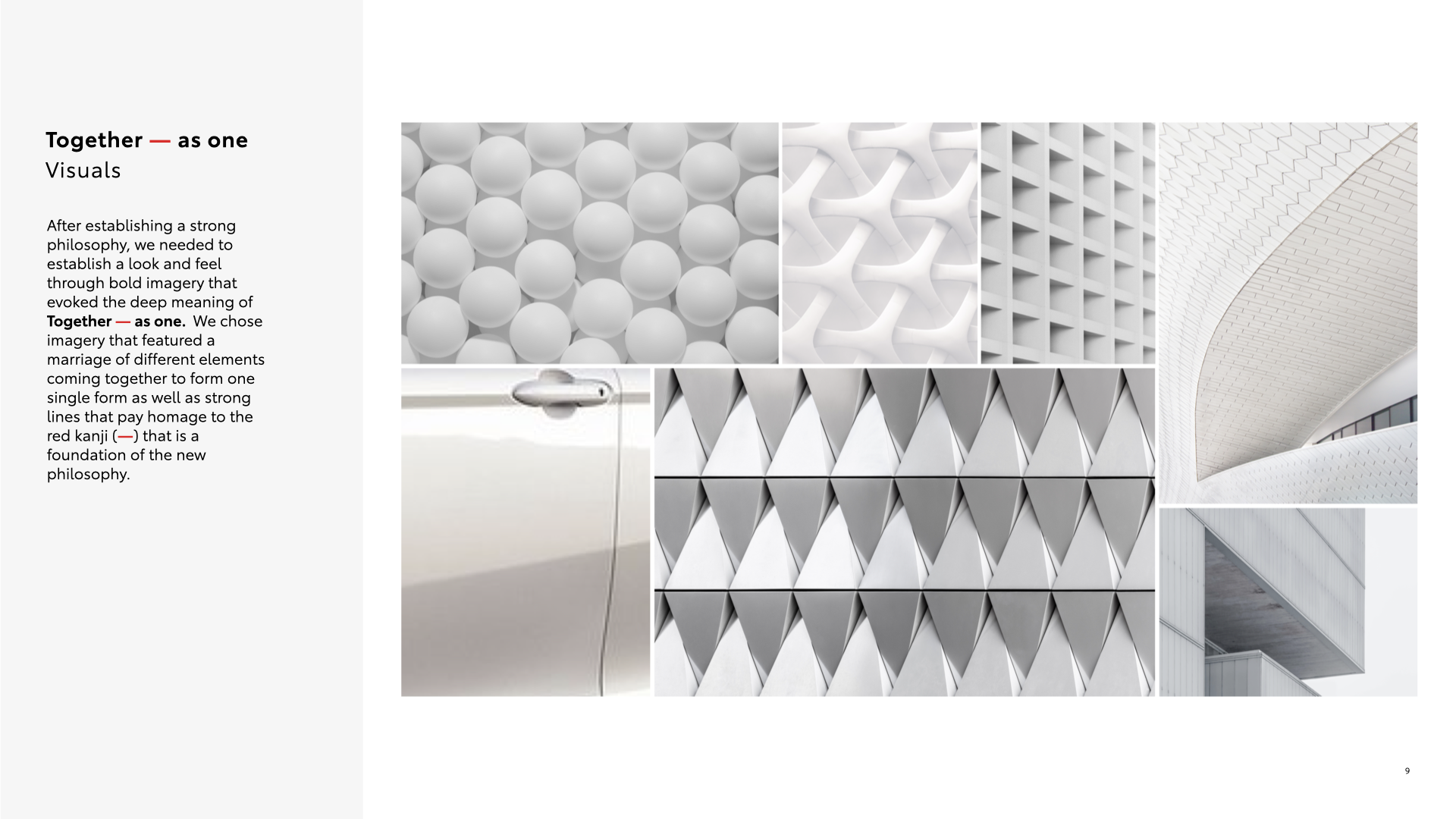

We evolved this idea of “one” even further, by developing the mantra Together — as one. This mantra is not just a phrase but a commitment, we wanted to express who the DSM team is and what their team culture is.

This philosophy is a marriage of an English phrase and the Japanese kanji ichi (—), meaning one. It is very much a reflection of our client North American division, while paying homage to its origins and parent company based in Japan. This phrase is also a symbol of DSM; they are a diverse team of individuals that come together, every day, to work as one.

Envisioning The Future

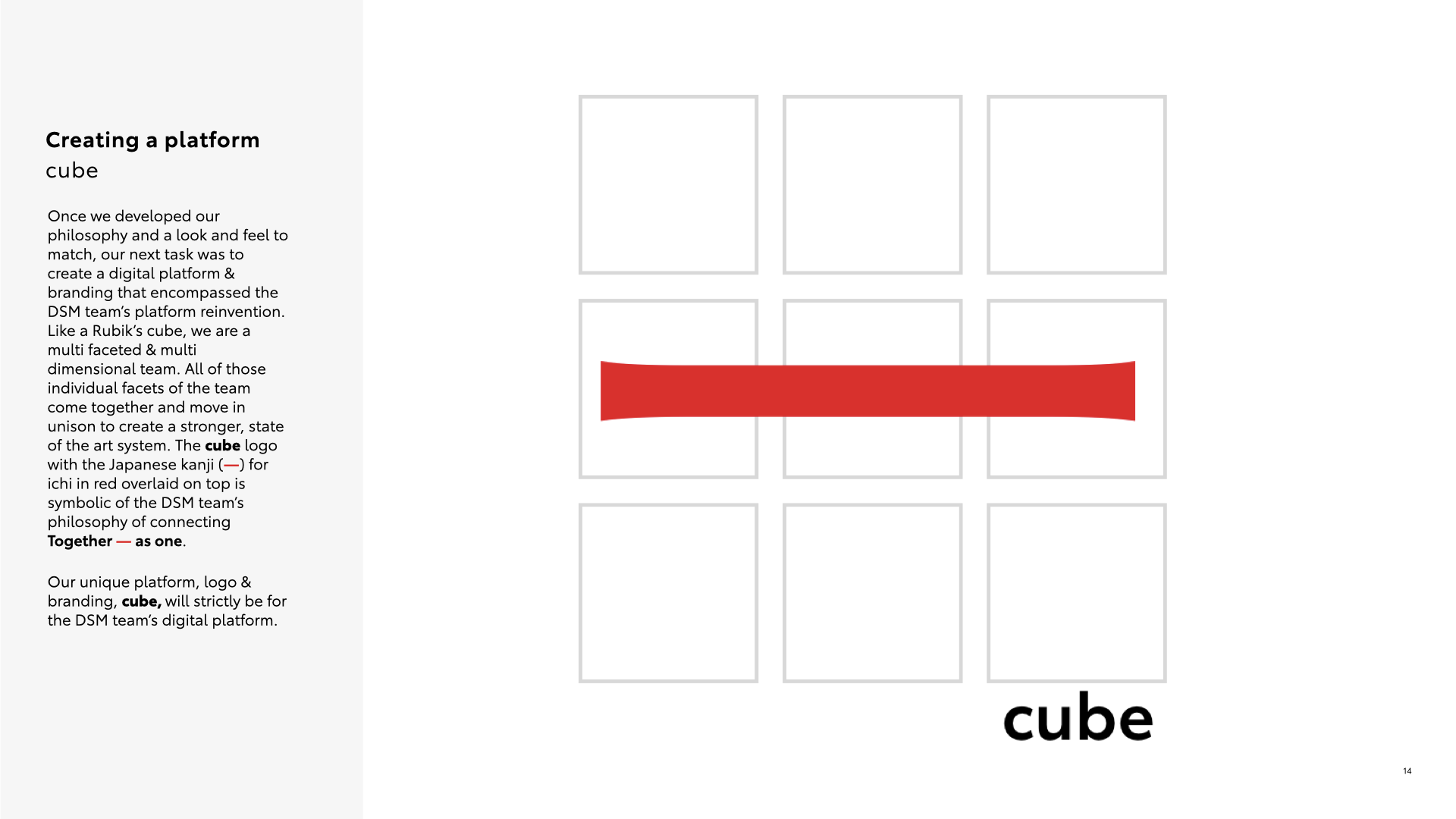

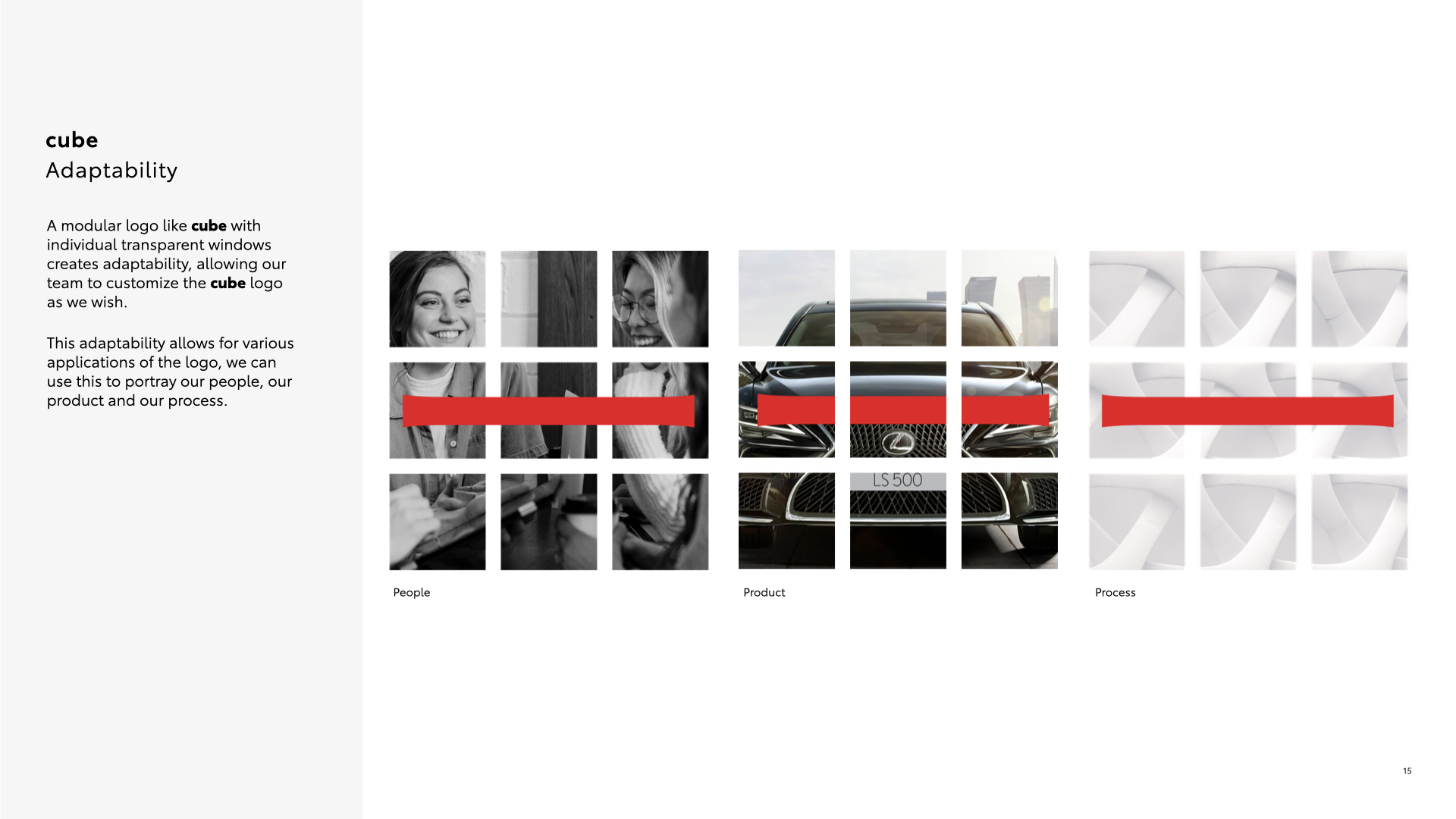

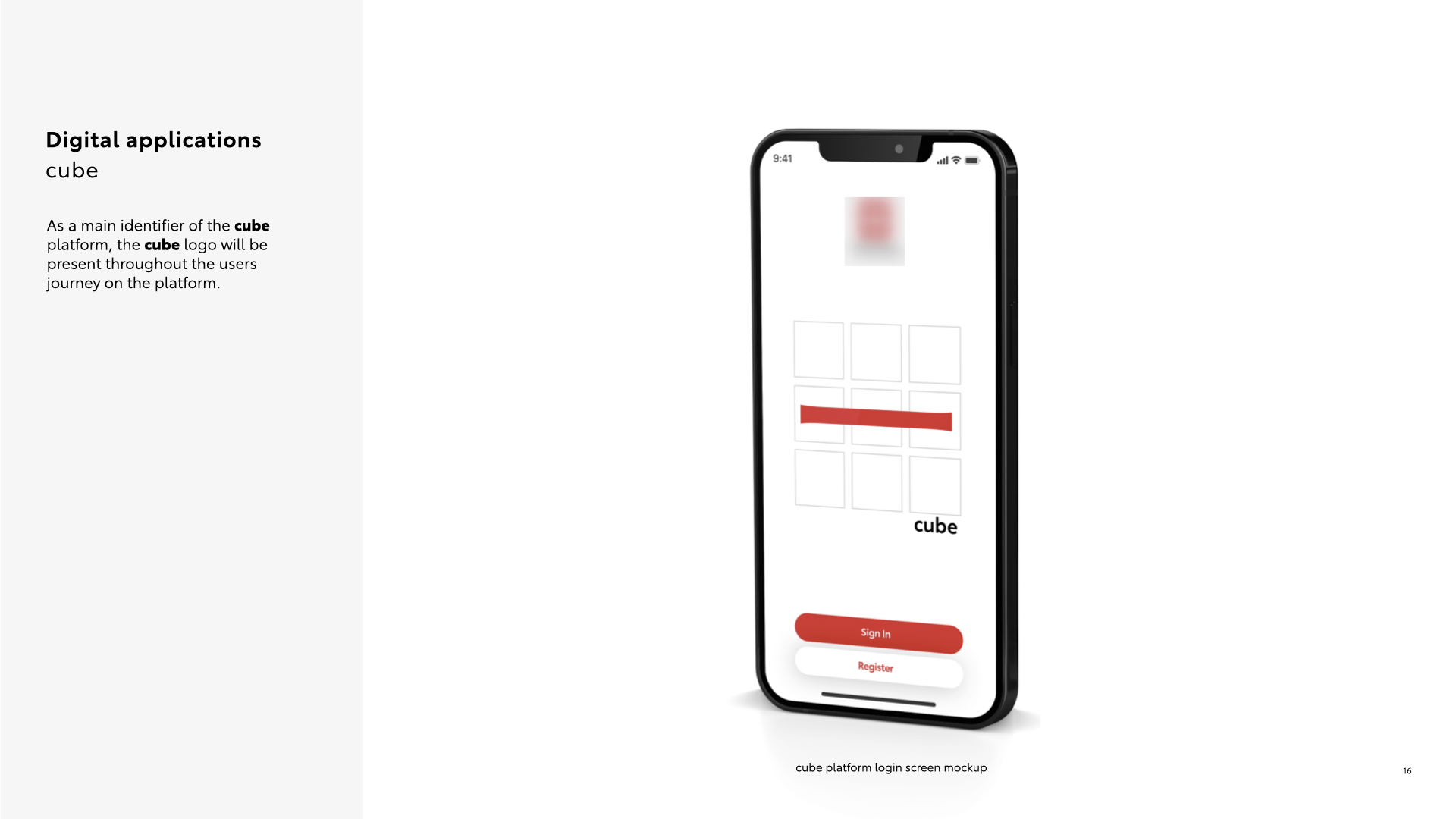

Once we developed the philosophy and a look and feel to match, our next task was to create a digital platform & branding that encompasses the DSM team’s platform reinvention. Like a Rubik’s cube, DSM is a multi faceted & multi dimensional team. All of those individual facets of the team come together and move in unison to create a stronger, state of the art system. The cube logo with the Japanese kanji (—) for ichi in red overlaid on top is symbolic of the DSM team’s philosophy of connecting Together — as one.

Our unique platform, logo & branding, cube, would strictly be for the DSM team’s digital platform.

Click through the slideshow below to see our full brand story we developed for our client’s demand & supply management (DSM) team.

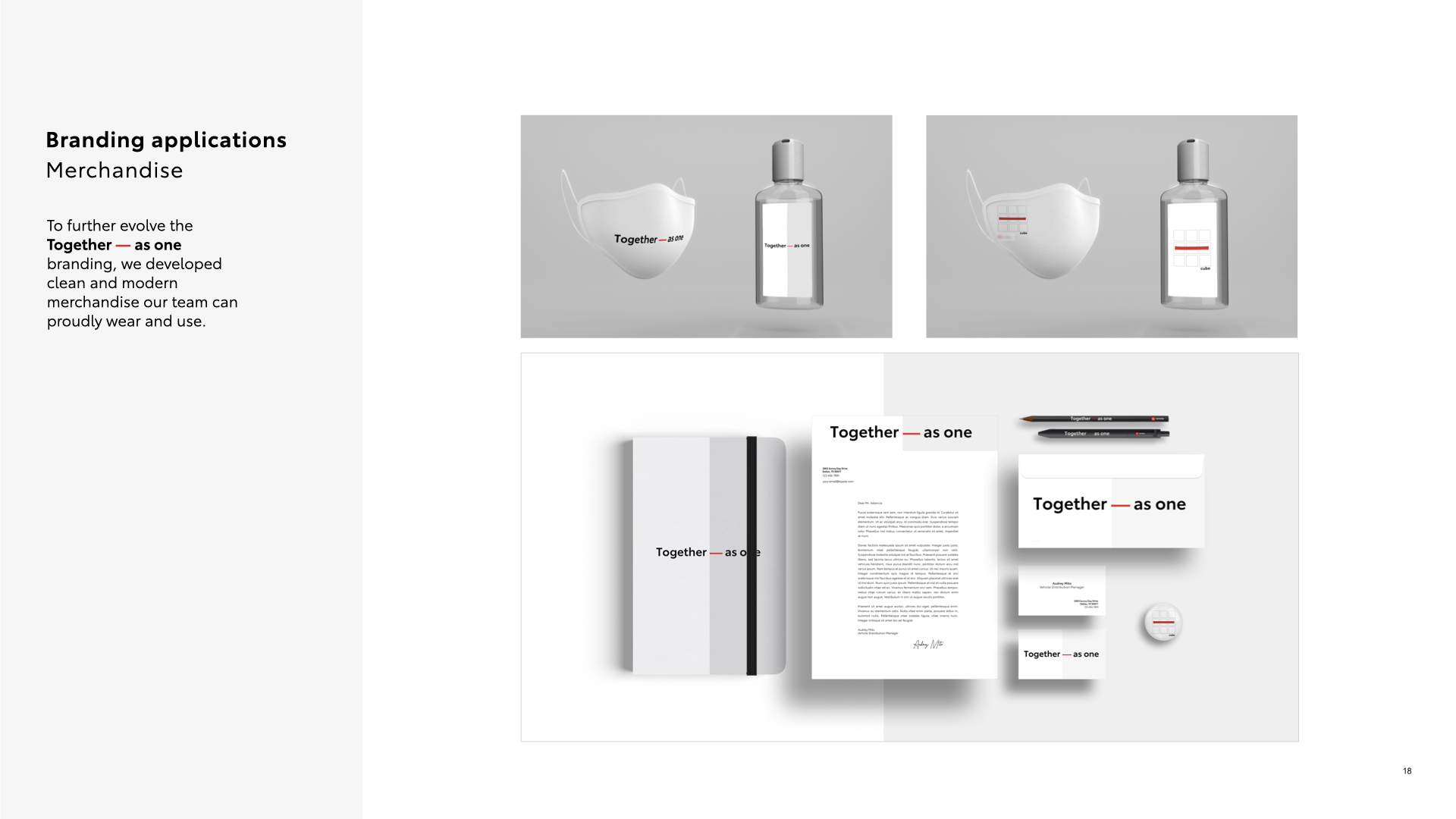

Additional branding application examples: in office murals and T-shirts

Part 2: Discovery Phase and Initial POc (proof of concept)

Research

Our team conducted hours of user research, including 1:1 user interviews (with stakeholders and our key user groups) across 2 weeks to discover the user’s main pain points they experience using their current vehicle monitoring systems, especially around a vehicle’s estimated time of arrival (ETA’S). Our team took turns interviewing the core users as well as taking detailed and extensive notes in both excel and word documents in order to gather as much user data as possible.

Sample of our team’s interview and notes template that was created in Excel in order for our team to track and organize and eventually leverage these insights during the user research synthesis phase.

After gathering all of the crucial data from the interviews, our team came together to analyze all of the data. Our team grouped and organized key data points and trends we noticed throughout our interviews in order to visualize commonalities amongst user paint points that could serve as a basis for design requirements.

What We Discovered

The organization as a whole struggled with outdated supply chain management systems, inaccurate estimated time of arrivals (ETA) for vehicle’s in their supply chain and were working in silo’d teams which led to misinformation as well as extreme delays in receiving information on a vehicle’s location and whereabouts.

solution

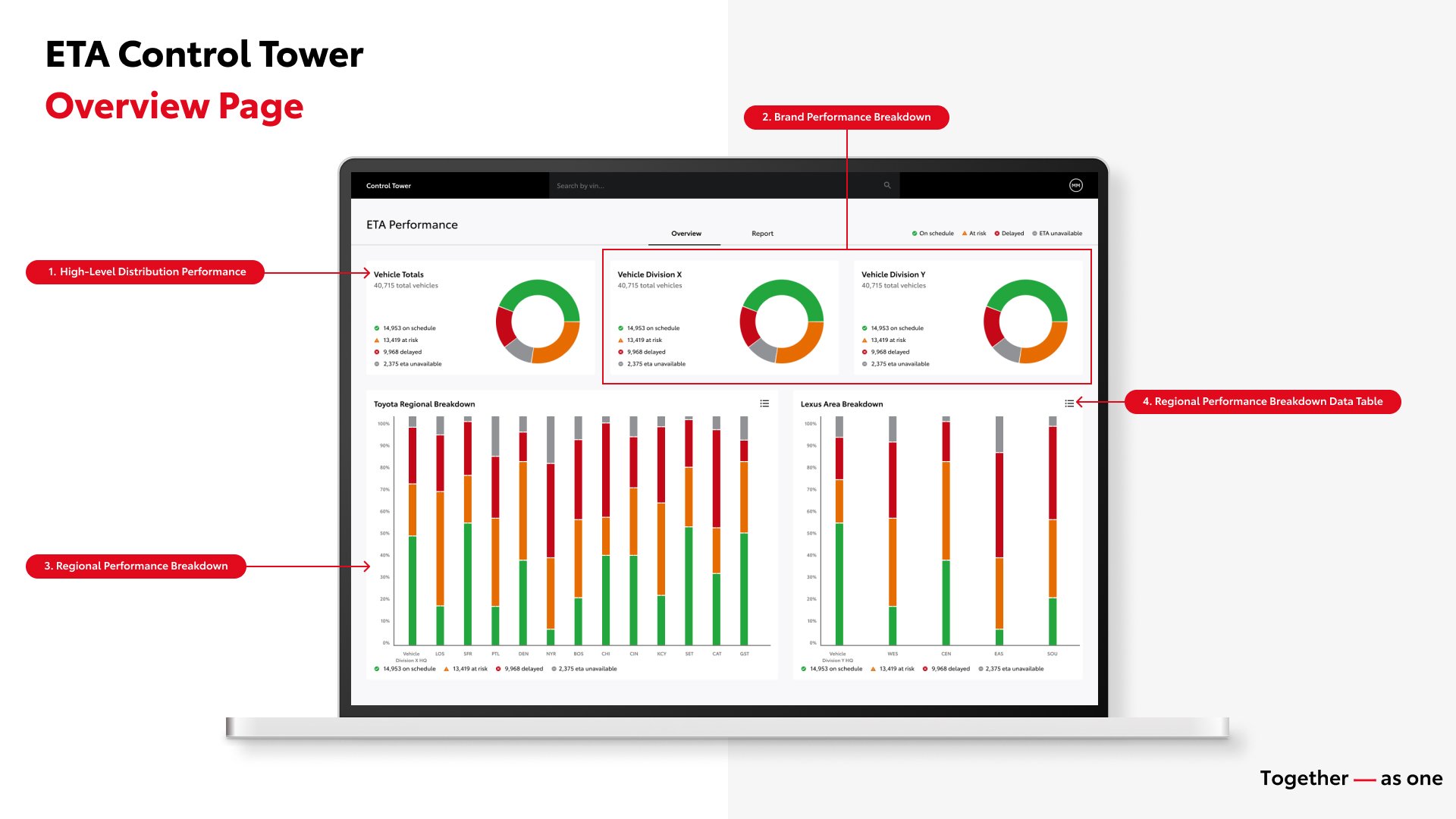

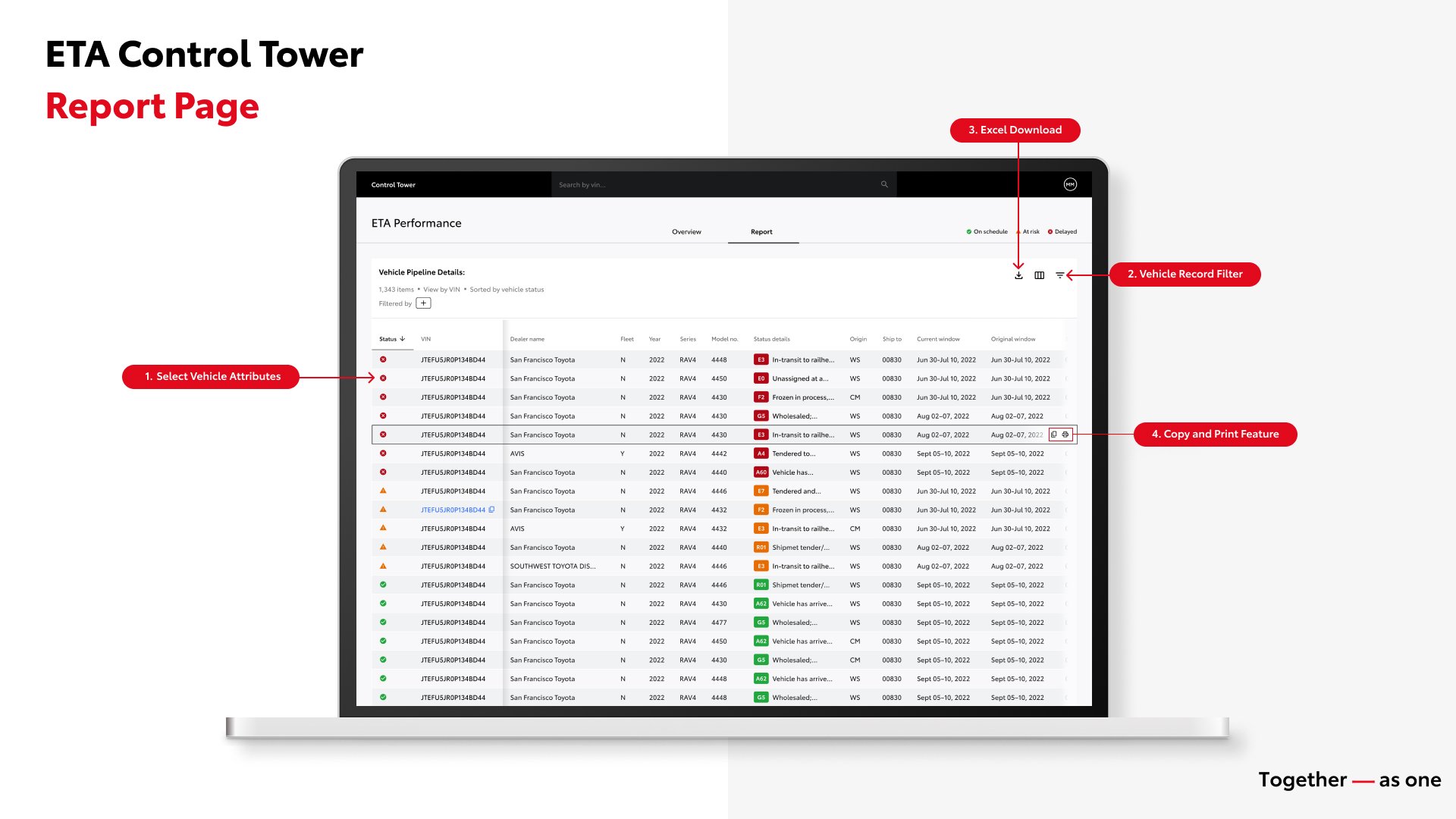

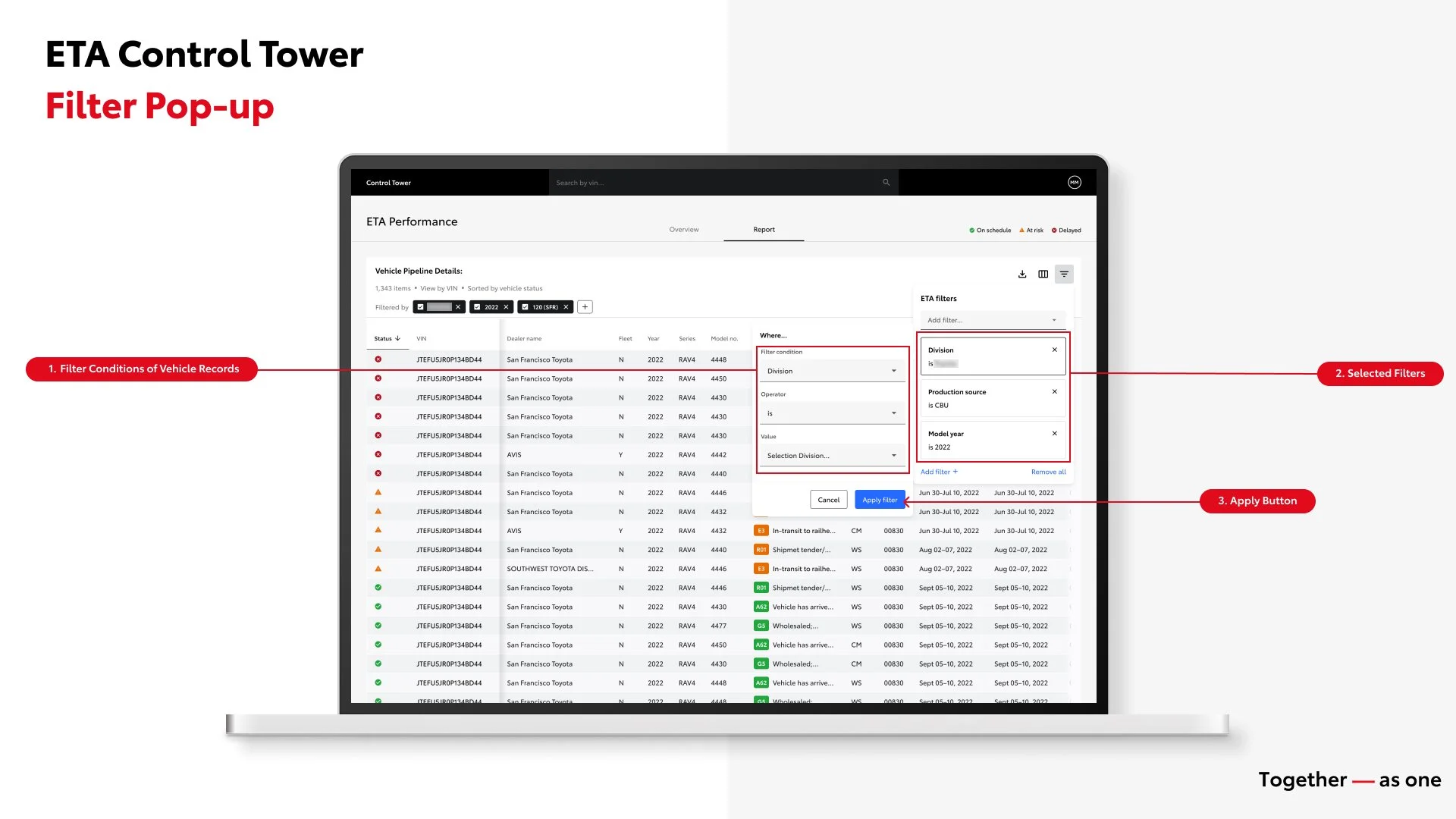

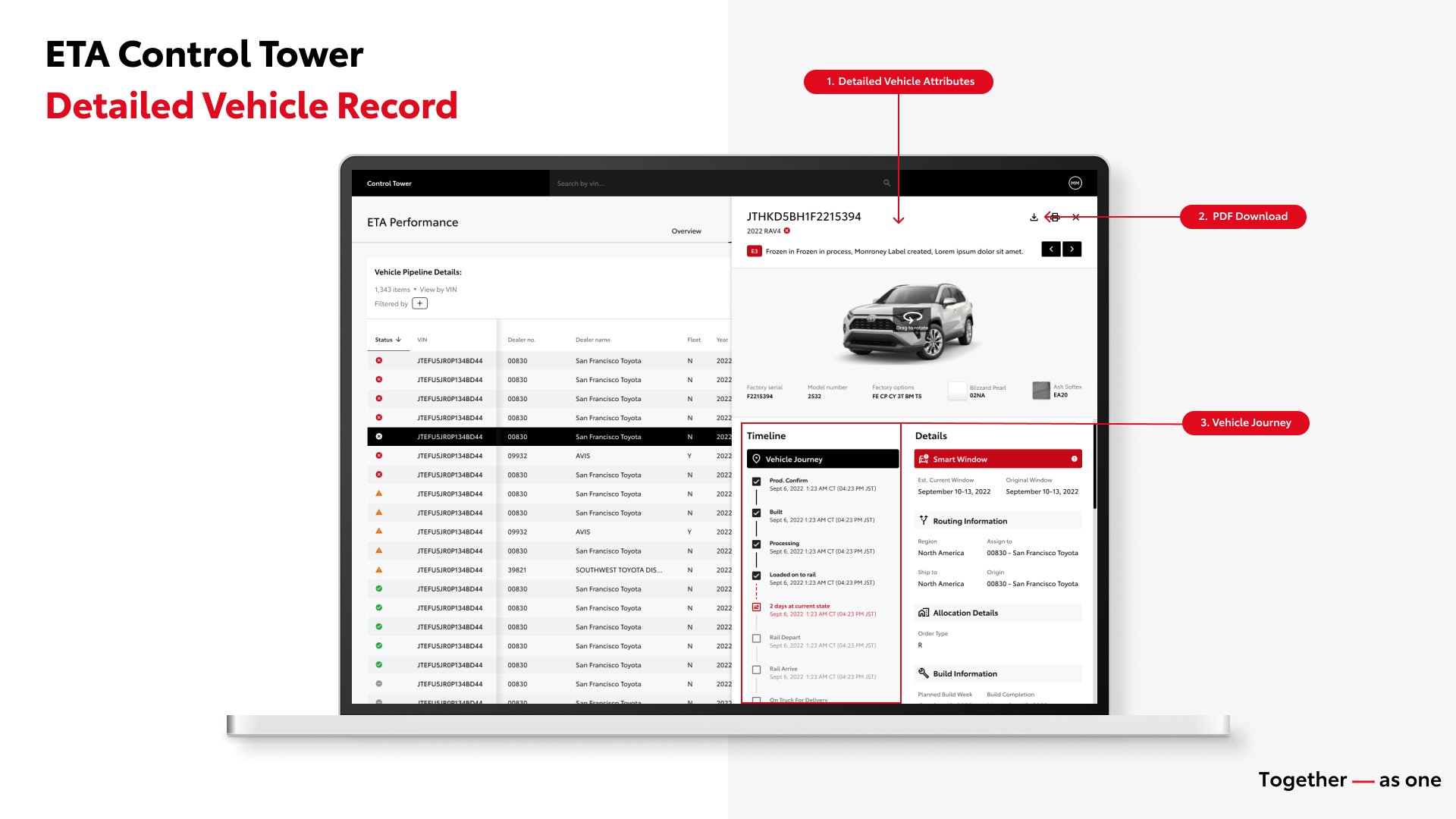

After months of user research, synthesis of data, workshops and design iteration, our solution to the client’s outdated supply chain monitoring system and ways of working was to create an ETA (estimated time of arrival) control tower, leveraging historical data, machine learning and AI to create a forecasted “smart ETA window” of when the vehicle or shipment of vehicles will make it to its destination. This control tower allows the DSM team to immediately determine which of their vehicle divisions (luxury division or economy division) is experiencing an extensive delay, and where and why that delay is occurring so that they can enact the required solutions to remedy the problem. This is all to ensure the vehicle or shipment of vehicles do not miss their calculated smart ETA window.

Initial POC design

Once we had our research, key findings and key persona developed, we had a strong foundation to work from to design and develop the Control Tower. Our team held multiple intensive workshops to develop the scope for the POC and ensure the key user needs and pain points were the core features of the POC. What our team developed was the innovative Control Tower, which was a vehicle supply chain dashboard with drill down capabilities that leveraged real time data to accurately predict when a vehicle would arrive to it’s destination.

The initial POC design leveraged the key takeaways from our research, a dashboard was dveloped where all high level ETA data could be viewed at a glance. The user could select any of the segments of the pie or bar charts to drill down further into the ETA data.

Our designs also incorporated a vehicle list view page, where all VIN’s within a specific division or region are listed out for further drill down of data.

A vehicle detail page was also developed, that would appear when a user selected a specific vehicle from the list view page, pulling up all vehicle & ETA details.

Pilot Evolution Design

After weeks of developing the initial POC design the client was so pleased with the result that they signed our team on to develop a pilot of the design so they could soft launch the Control Tower to a small pool of users to gain feedback and continuously iterate upon the control tower designs .

The pilot UI evolution was focused on refining all that we had accomplished during the POC phase of the project, but enhancing and refining the look and feel of the user interface and experience based off of feedback we received from key users and stakeholders.

Results

The dedication, time and effort we put into the creation of the Control Tower POC & pilot, lead to our team winning a $25 million dollar contract from the client in order to continue our work on revolutionizing their supply chain systems.

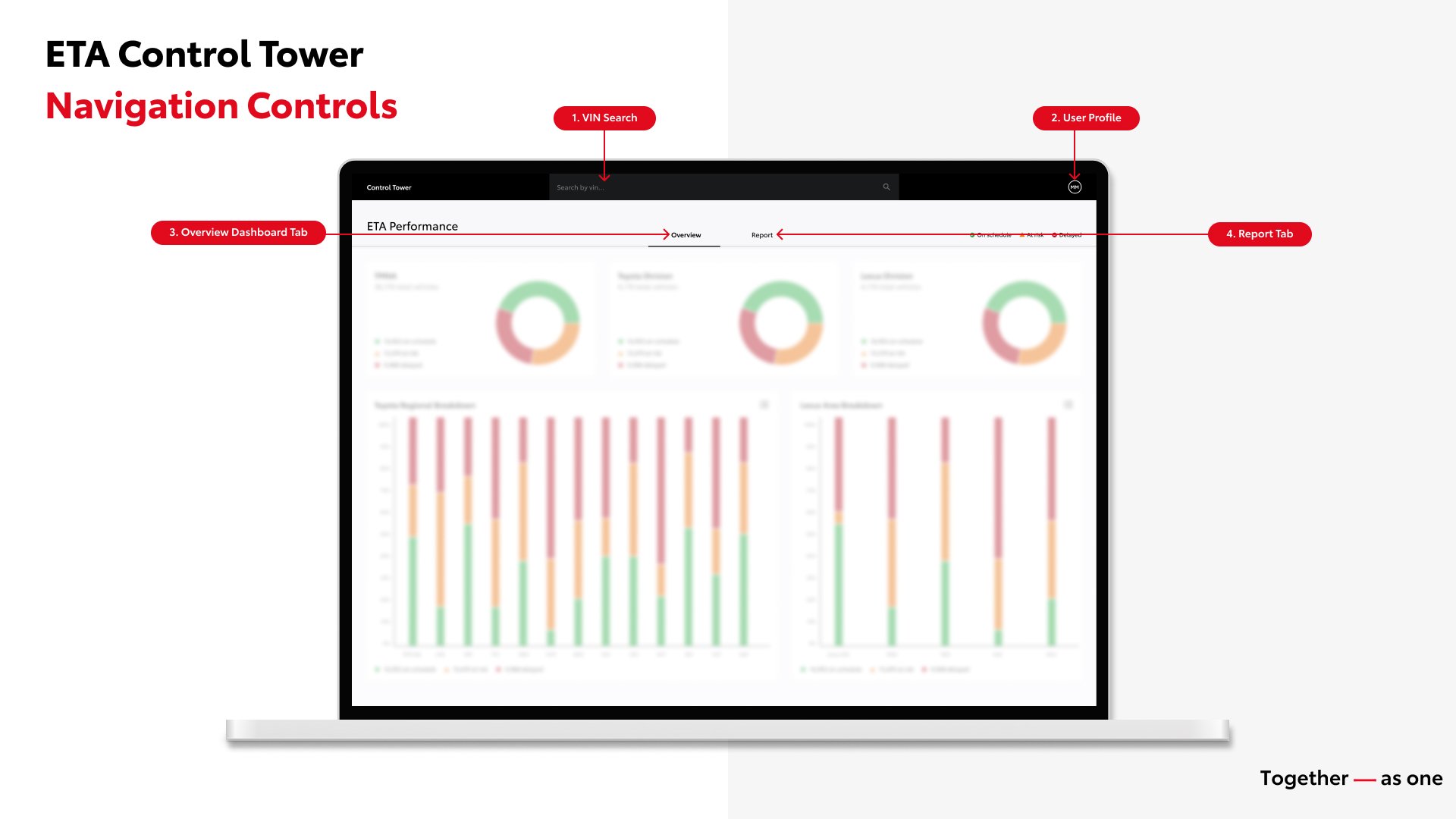

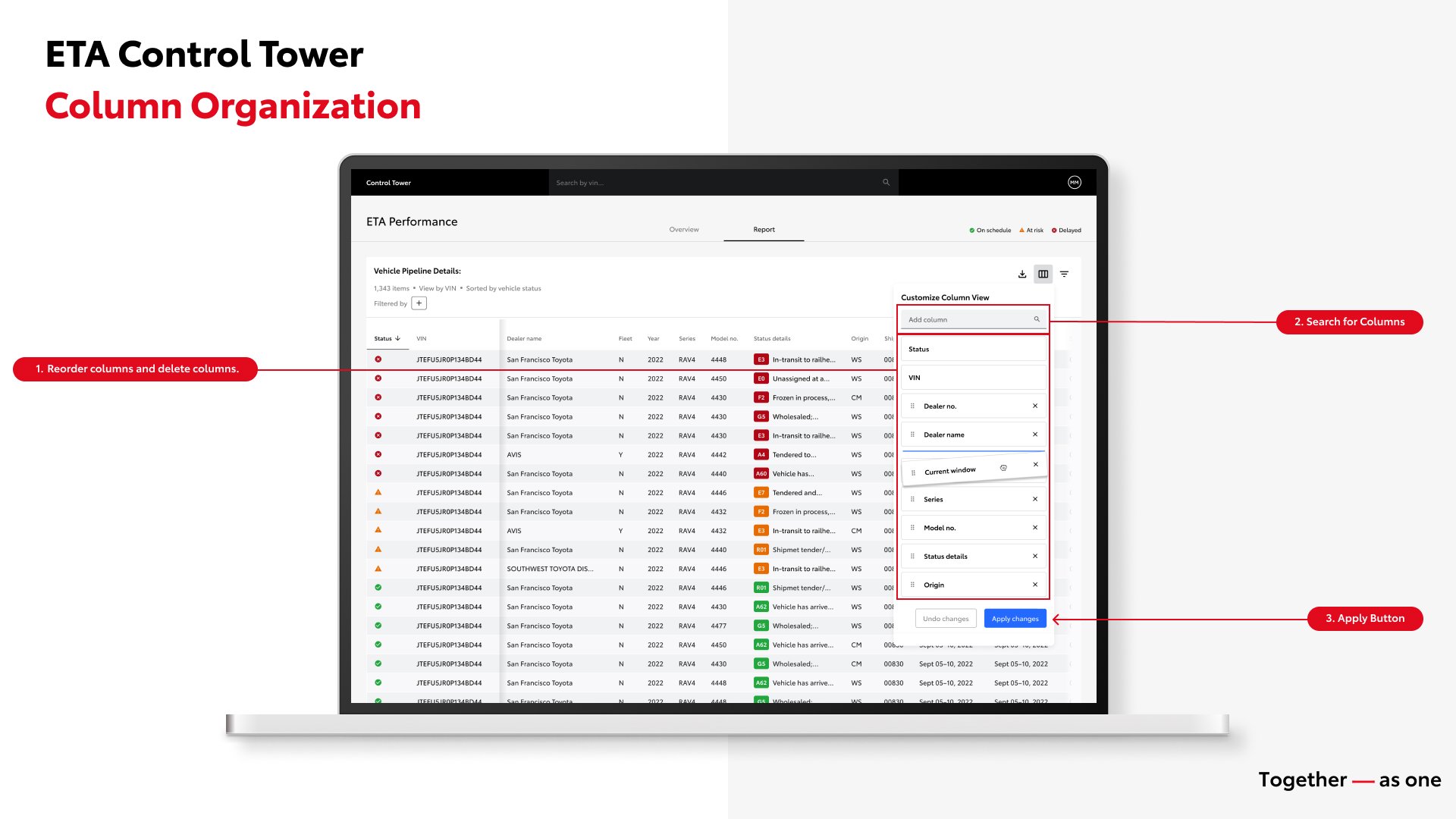

Part 3: Final Evolution & Product Design for launch

After the success of the pilot designs, we were extended by the client to develop and iterate upon the designs for the initial launch of the Control Tower. We worked closely with our development team to evolve our initial pilot and POC designs to re-imagine the look and feel and functionality of the Control Tower. Click through the slideshow below to see all of the features and functionality of this innovative tool.

ETA Control Tower Responsive Designs (Mobile)